Three-quarters of the Earth’s surface is composed of water and because humans need water, most of humanity lives in coastal regions. Construction is a big part of human activity and has an obvious impact on the environment. Human survival depends on the health of the ecosystem. Marine construction projects such as dredging, bridges, roads, marinas and ports affect marine life and plants. That is why it is critical to mitigate the negative effects of suspended sediments during construction with the use of turbidity silt curtains, which act as a barrier between the work area and the rest of the water.

These silt curtains are devices that control turbidity and suspended solids in the water generated by dredging or discharge water pipes. The challenge for marine construction contractors is to figure out how to select the right equipment for a particular application. This article aims to help contractors and estimators choose the right system.

Definitions

- Dredging: “Dredging is an excavation activity or operation usually carried out at least partly underwater, in shallow seas or freshwater areas with the purpose of gathering up bottom sediments and disposing of them at a different location.” – Wikipedia

- Turbidity: “Cloudiness or haziness of a fluid caused by large numbers of individual particles that are generally invisible to the naked eye, similar to smoke in air. The measurement of turbidity is a key test of water quality.” – Wikipedia

- Silt: “Granular material of a size somewhere between sand and clay whose mineral origin is quartz and feldspar. Silt may occur as a soil or as sediment mixed in suspension with water (also known as a suspended load) in a body of water such as a river. It may also exist as soil deposited at the bottom of a water body.” – Wikipedia

- Sediment: “Sediment is a naturally occurring material that is broken down by processes of weathering and erosion, and is subsequently transported by the action of wind, water, or ice, and/or by the force of gravity acting on the particles”. – Wikipedia

- Silt/Turbidity Curtain: Device that usually consists of floats, cables, a skirt and anchors designed specifically to control silt, sediments and turbidity generated in the water by marine construction equipment.

Types of silt curtains

Selecting the right turbidity barrier is critical to ensure the structure works well for a particular application. The first factor in the selection process is water conditions:

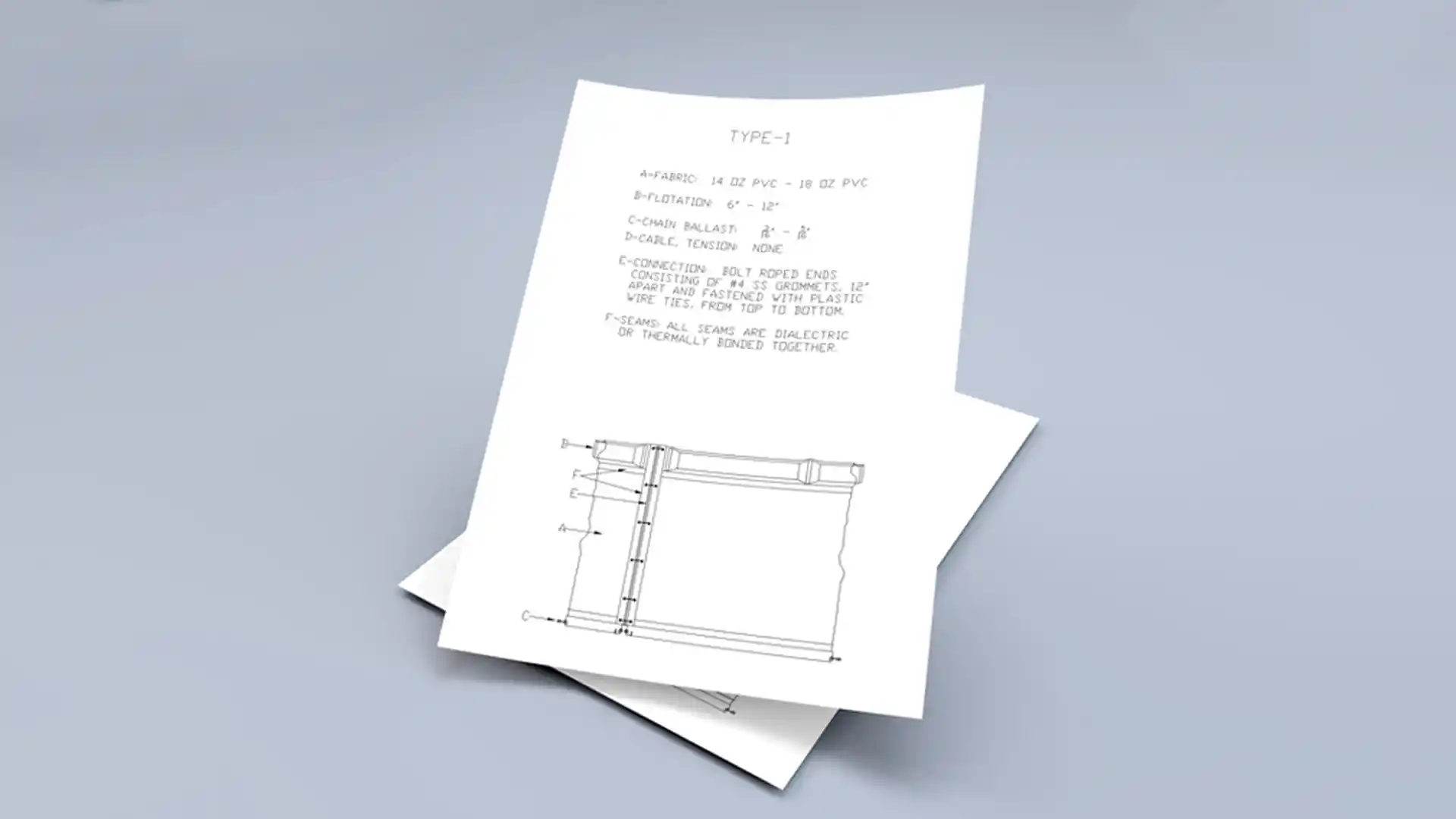

TYPE 1 Silt Curtain for calm water applications:

Typically, small ponds and lakes, canals and waterways with light wind or current fall in the type 1 category. The industry also refers to light duty curtains for these calm water applications.

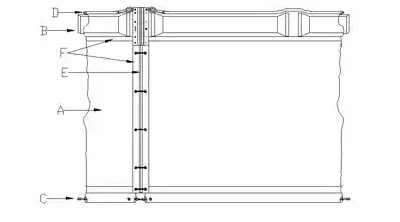

TYPE 2 Silt Curtain for moving water applications:

Typically, Type 2 silt barriers are for rivers, harbors, protected ports with some wind or current. The industry also refers to medium duty curtains for these moving water applications.

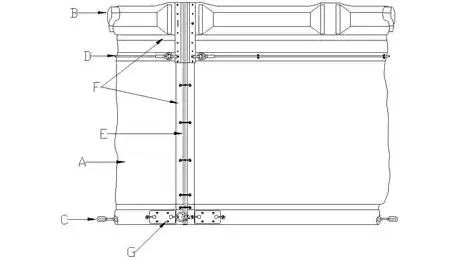

TYPE 3 Silt Curtain for tidal water applications:

The Type 3 is considered a heavy-duty turbidity curtain and is built to handle substantial wind, current and tidal forces in some ports applications, shoreline and offshore.

Float size, skirt depth and quantity of cables, play a role in being a type 1, 2 or 3 silt curtain.

The second criteria is skirt permeability:

Permeable skirt: The material of the skirt will allow some water to flow through, while still containing and confining silt and sediment to the immediate work area. It also relieves stress on the curtain or the entire system. A permeable skirt prevents or reduces ballooning of the skirt, which is due to currents, tide changes and having a deep skirt.

Non-permeable skirt: The skirt does not allow water to pass through the membrane.

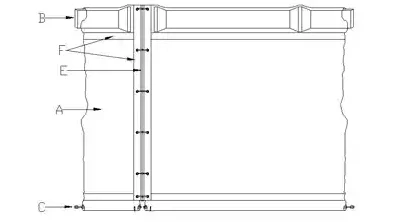

Turbidity Curtain Components

A system usually consists of the following parts:

- Fabric (A on above drawings): Varies from 14 oz. PVC to 22 oz. PVC depending on the Type 1, 2 or 3 model.

- Floats (B): They vary in size from 6″-12″ to 8″-12″ depending on the models.

- Chain Ballast (C): Its function is to keep the skirt in a vertical position.

- Tension Cable (D): Enviro-USA’s Type 1 silt curtain does not have a tension cable, while Type 2 has one cable and Type 3 has two cables. The function is to absorb stress imposed by currents and turbulence.

- Connectors (E): Curtains are usually built-in sections. Connectors allow the sections to be joined together to accommodate the total length of the area to contain.

- Seams (F): All seams are dielectric or thermally bonded together.

- Stress Plates (G): Featured on the Type 3, the chain loads are distributed through aluminum plates bolted back-to-back on each side of curtain and then transferred from curtain to curtain via HG hook and ring for strength and ease of assembly.

Typical Silt Curtain Installation

After the site has been surveyed, the design process leads to the selection of the right equipment and specifications for a particular project. Part of the design is the deployment configuration.

There are several ways to install turbidity curtains. Below are some of the typical deployment configurations possible:

- Maze configuration: This design has been used on rivers with boat traffic but is not a recommended option because of the current.

- “U” configuration: While this method can work in some applications, the challenge is to contain turbid water within the “U” shaped curtain as water and sediments may tend to overflow.

- Semi-circle configuration: In some applications, turbidity is caused by a discharge water pipe. In this case, the curtain is set in a semi-circle shape and is anchored to the shore on both sides.

- Circular configuration: This design is typically used on tidal applications and will allow the curtain to handle the current from the work area and reversing current from the wave action.

Get a Free Quote:

Enviro-USA offers its marine construction customers a Free Quote page where you can send us your specific requirements and specifications for the turbidity barrier of your needs. Just click on the button below to fill out a form and reach us.

You will get a quick turnaround, recommendations and a cost estimate.